|

BIOMASS:

Biomass has been a major energy source, prior to the

discovery of fossil fuels like coal and petroleum. Even

though its role is presently diminished in developed

countries, it is still widely used in rural communities of

the developing countries for their energy needs in terms

of cooking and limited industrial use.

Biomass is a natural substance available, which stores

solar energy by the process of photosynthesis in the

presence of sunlight. It chiefly contains cellulose,

hemicellulose and lignin, with an average composition of C6H10O5,

with slight variations depending on the nature of the

biomass.

Biomass has always been an important energy source for the

country considering the benefits it offers. It is

renewable, widely available, carbon-neutral and has the

potential to provide significant employment in the rural

areas. Biomass is also capable of providing firm energy.

About 32% of the total primary energy use in the country

is still derived from biomass and more than 70% of the

country’s population depends upon it for its energy

needs.

The Government of Madhya Pradesh has taken note of the

growing recognition of impacts of climate change and

recognizes the need to tackle challenges that arise on

account of these impacts through integrated policy

prescriptions and programmes aimed at mitigation of

impacts and adaptation to reduce vulnerability of systems.

Based on this green initiative, by endorsing the essential

need to prevent avoidable erosion of natural carbon –

energy resources the state is endowed with, the state is

committed to promote promotion of generation of

electricity from Renewable Energy sources.

Potential:

The ‘Biomass Resource Atlas of India” projects the gross

potential for energy generation from Agricultural sources

at 1386.2 MWe and 2060.6 MWe from forests ,wastelands

respectively in the state of Madhya Pradesh.

The biomass wise potential in the state has been given

below:

|

Biomass |

Power Potential

(kWe) |

|

Husk |

248.161 |

|

Stalks |

886.57 |

|

Leaves |

561.467 |

|

Cobs |

41.08 |

|

Shell |

158.11 |

|

Bark |

477.15 |

|

Residue |

0.3 |

|

Branches |

477.15 |

|

Others |

0.06 |

|

Twigs |

477.15 |

|

Straw |

44 |

|

Pod |

75.3 |

Achievement:

Biomass based power projects with a cumulative capacity of

around 32 MW has been commissioned in the state as on 19

November,2010.

Technology:

1.

Bagasse based Co-generation :

In

simple terms, cogeneration is the process of using a

single fuel to produce more than one form of energy in

sequence. Cogeneration of steam and electricity can

significantly increase the overall efficiencies of fuel

utilization in process industries. A minimum condition for

cogeneration is the simultaneous requirement of heat and

electricity in a favourable ratio, which is well fulfilled

in the sugar industry. The thermodynamics of electricity

production necessitates the rejection of a large quantity

of heat to a lower temperature sink. In normal electricity

generation plants, this heat rejection takes place in

condensers where up to 70% of heat in steam is rejected to

the atmosphere. In cogeneration mode, however, this heat

is not wasted and is instead used to meet process heating

requirement. The overall efficiency of fuel utilization

can thus be increased to 60% or even higher in some cases.

Capacity of cogeneration projects can range from a few

kilowatts to several megawatts of electricity generation

along with simultaneous production of heat ranging from

less than a hundred kWth (kilowatts thermal) to many MWth

(megawatts thermal).

2.

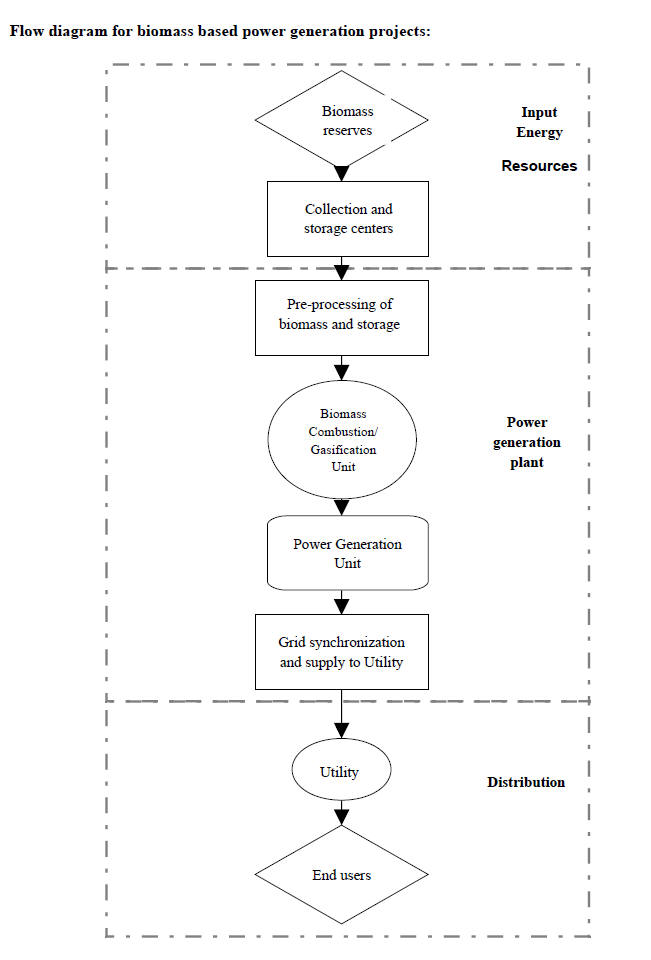

Biomass based Power Generation :

The technology for generation of electricity from these

biomass materials is similar to the conventional

coal-based thermal power generation. The biomass is burnt

in boilers to generate steam, which drives a turbo

alternator for generation of electricity.

3.

Biomass Gasification :

Biomass gasification is thermo-chemical conversion of

solid biomass into a combustible gas mixture (producer

gas) through a partial combustion route with air supply

restricted to less than that theoretically required for

full combustion. Typical composition of producer gas is

Carbon Monoxide (18%-20%), Hydrogen (15%-20%), Methane

(1%-5%), Carbon dioxide (9%-12%), Nitrogen (45%-55%). The

calorific value of the producer gas is in the range of

1000-1200 kcal/m3.

|